I

started by bolting the propshaft to the sprocket adapter only to realize that

there was a lot of movement on the splined shaft. I undid the 4no bolts, removed the sprocket

cover and then removed the sprocket adapter.

It appears that when I tightened it up some months ago, the washer had

slipped and was trapped against the end of the splined shaft. This meant when it was tightened the nut was

trapping against the washer, not the sprocket adapter, meaning there was

movement. I retightened it with more

Loctite and that seemed to sort it out.

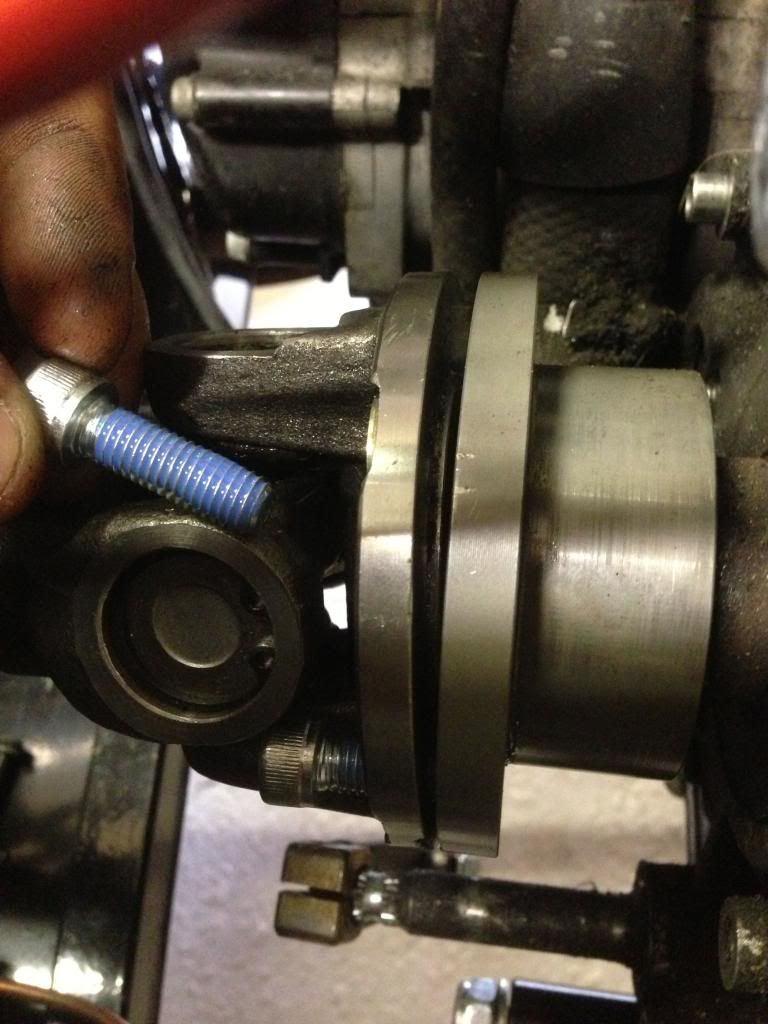

I

again tightened the propshaft to the sprocket adapter with 4no M8 x 30mm 12.9

socket cap bolts. These were longer than

needed for the speed sensor.

The

speed sensor on the GSXR is a magnet that detected when the rotor passed

infront of it, 4 times per revolution. I

positioned the speed sensor under the sprocket adapter and made an aluminium

bracket to hold it in position. I fixed

this using an M6 hole in the engine block that wasn’t needed anymore. The speed sensor is positioned so it is 1mm

away from the bolts so one revolution should be 4 detections, the same as it

was on the bike.

I

also fitted the other rear wheel only to find that one of the handbrake springs

was rubbing. I removed the spring and

crushed it in the vice to reduce its height slightly. Refitting was hard work but once in position

there is about 3mm of clearance to the wheel now.

Last

job was to bolt the other end of the propshaft to the diff. I only put 2 of the bolts in for now so I

could test the reverse. It works but it

is noisy!!

M8 socket cap bolts installed with loctite

Sprocket cover back in position

Bolts left long intentionally

Aluminium bracket for speed sensor

Speed sensor mounted to spare M6 hole in engine block

Bolts come within 1mm of speed sensor, 4 bolts per revolution

No comments:

Post a Comment