First job was the gear indicator. I bolted the bracked to the angle pieces I stuck to the dash yesterday. This holds the gear indicator in position and no fixings can be seen.

Next, having

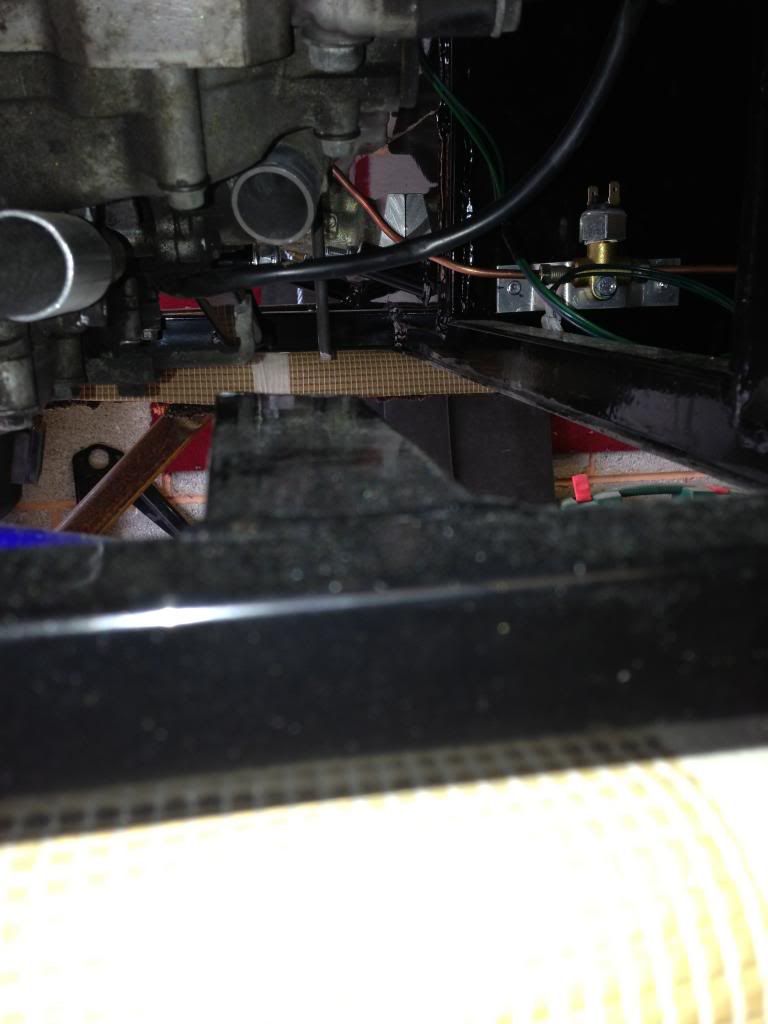

decided on the position of the header tank (to the side of the steering column), I needed to decide how to mount it. I

thought that simply fixing to the fiberglass wouldn’t be strong enough and

would run the risk of the fixings coming loose so I made a bracket that will

fit behind the fiberglass and spread the load.

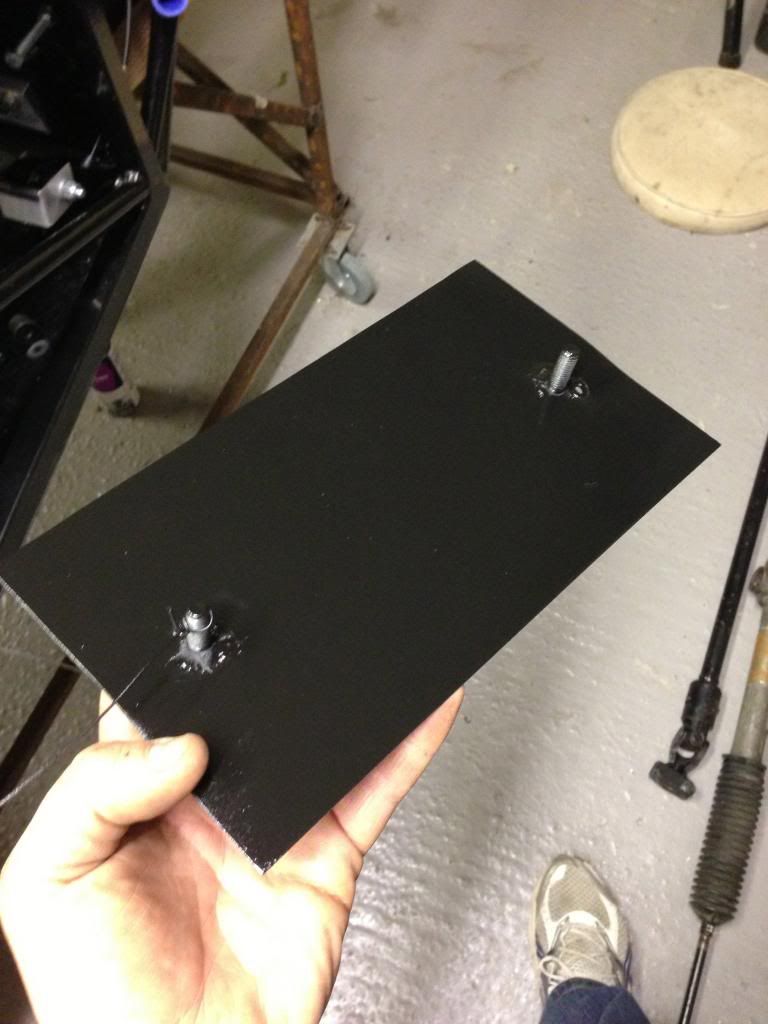

I used some 1mm steel plate, drilled holes in it to match the holes n

the header tank and welded 2no M8 bolts into it. This will eventually be fixed behind the

fiberglass with sikaflex so that only the two bolts can be seen sticking

through for the tank to bolt to.

Next

job was the gearshift bracket. I chopped

up a piece of 4” hollow square section and made the bracket similar to what was

on the chassis originally but offset 40mm.

I drilled 4no 5mm holes to bolt the new bracket to the original.

Then

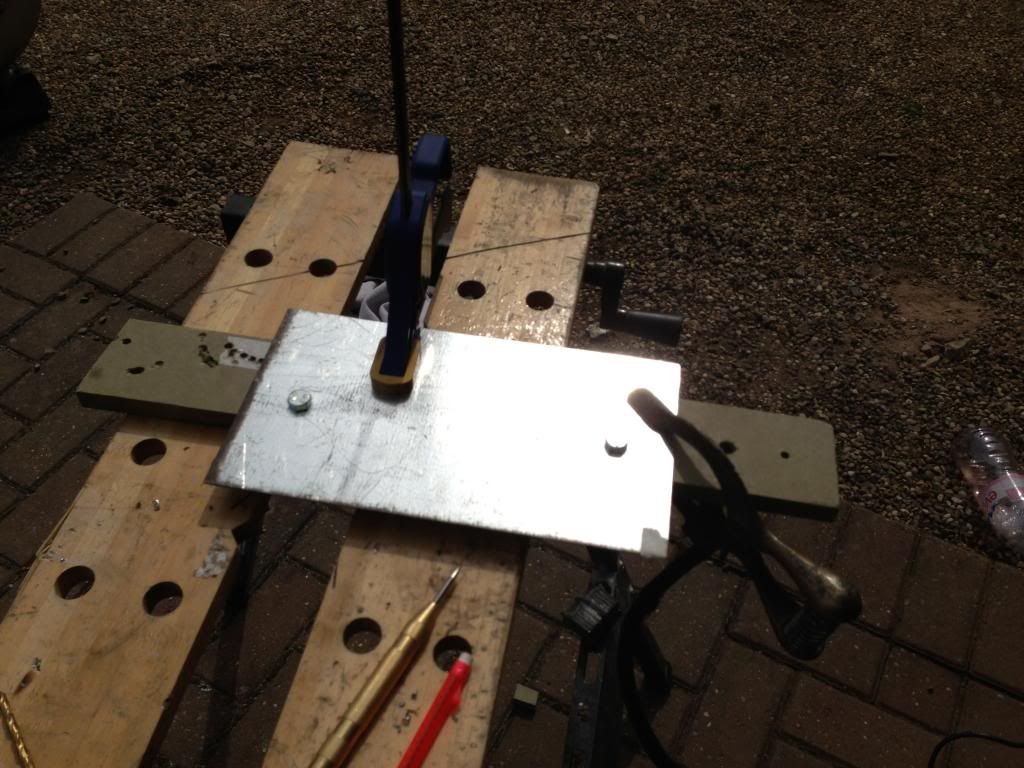

I tried to made a beading tool to put a bead on the alloy tube that will join

the silicone hoses together (the bead is needed to stop hoses coming

undone. I had seen a couple of ideas on

Locostbuilders and the first one I tried was a modified set of molegrips. This idea worked well on 1.2mm sheet

aluminium but didn’t work on the much tougher alloy hose. I then made another beading tool from scratch,

again from an idea I had seen on Locostbuilders but this one used the vice to

press so had must more force behind it.

This did a decent job of pressing in a bead, expanding the tube by about

1.5mm which should be plenty to stop the hoses sliding off.

Proposed position of expansion tank

Piece of 4" square section

16mm hole for gear shift cable

New and existing brackets together

Existing bracket end cut off. Looks like theres loads of room for cooling hose now!

4no. M5 bolts foxing bracket in position. Holes offset due to stiffener under bracket

Pipe beading tool made from pair of mole grips

Works well on 1.2mm aluminium. Didnt work on tougher alloy tube

2nd attempt at beading tool - open position

closed position

gear shift bracket painted

expansion tank bracket painted

No comments:

Post a Comment