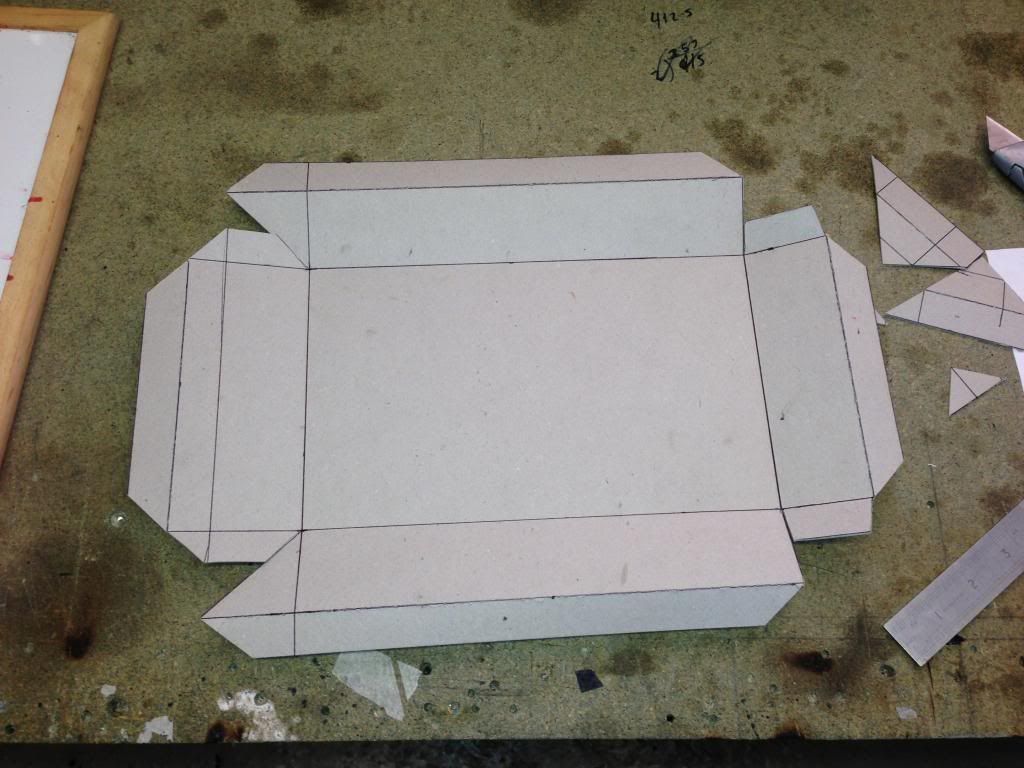

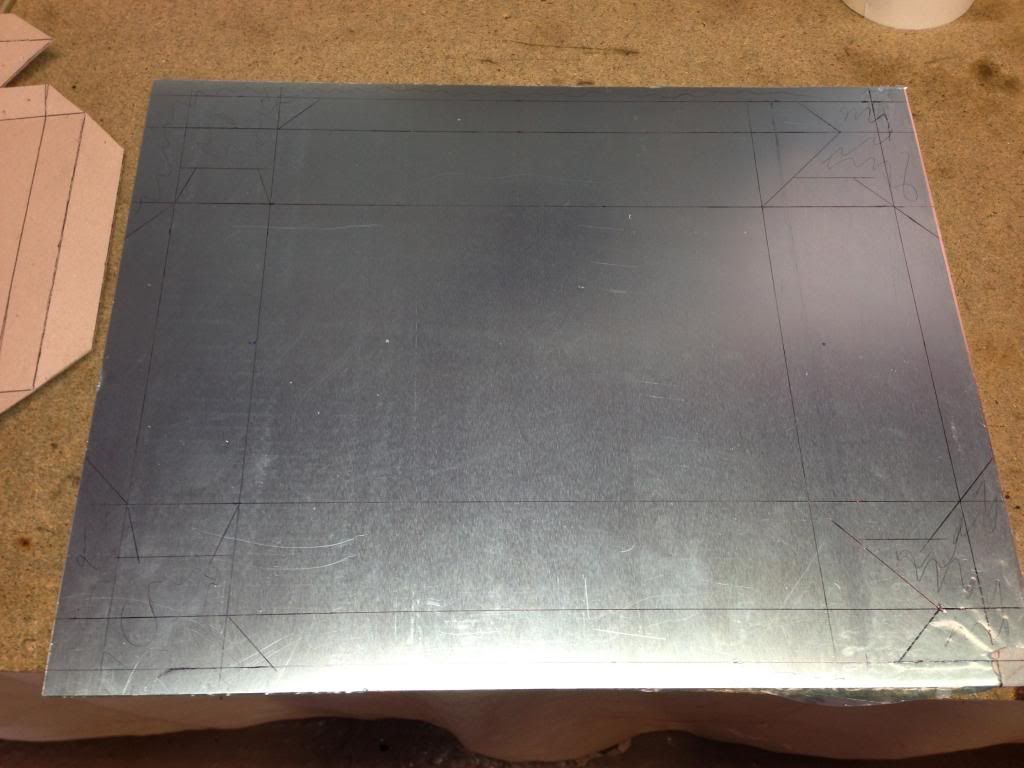

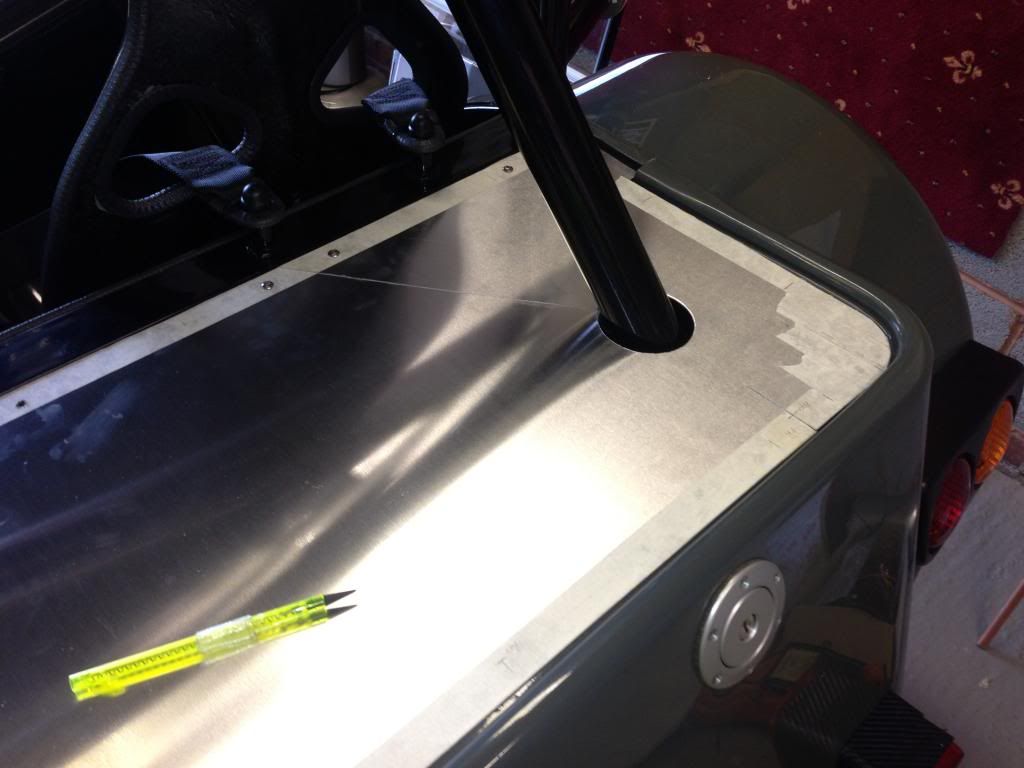

I decided to install a couple of panels under the dash on both drivers and passengers side to hide any sharp edges from the kill switch or the steering column. I cut two pieces of 0.9mm aluminium to size, approx 320x400mm, and drilled two holes for mounting underneath the bulkhead steel.

This was awkward and I needed to remove the fibreglass bulkhead to get access. Also marking, centre punching, drilling and installing rivets upside down is pretty tricky and I had to use a mirror to see what I was doing.

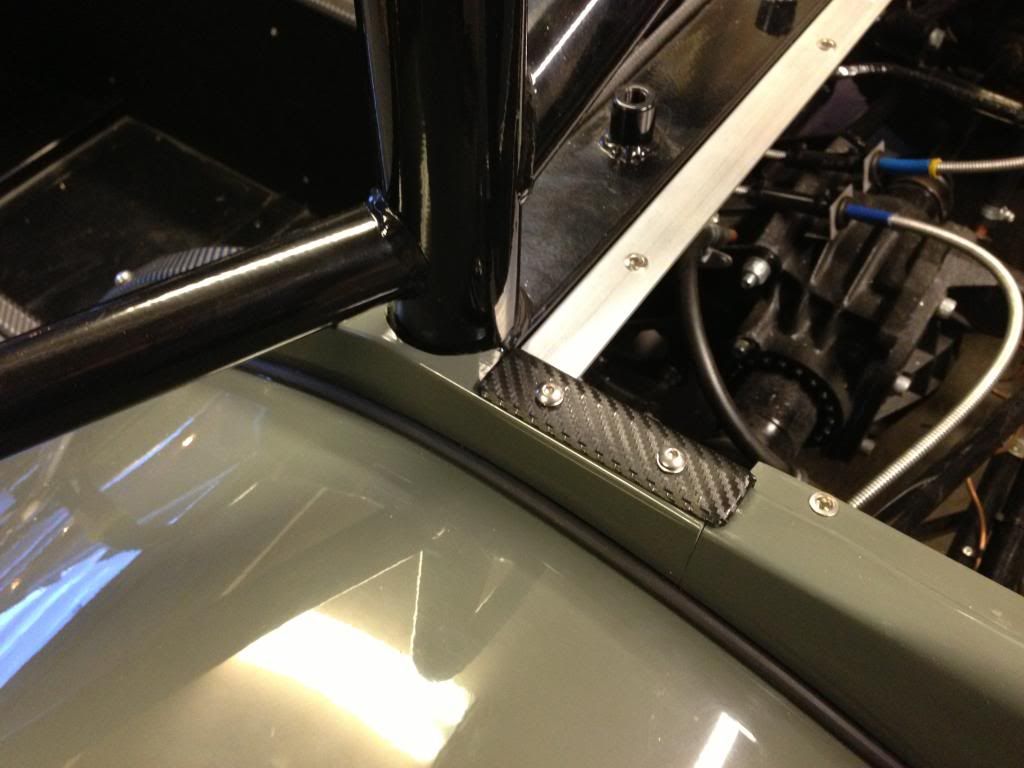

I stuck some edge trim on the sides of these panels and also on the bottom edge of the dash. The finished result looks tidier and will be better for the IVA. I may get the two panels powder coated so they blend in better also.

Aluminium panel - edge trimmed and adhesive foam to stop vibration. The panel is only fixed at one end. It rests against the underside of the fibreglass and is in tension so it quite secure.

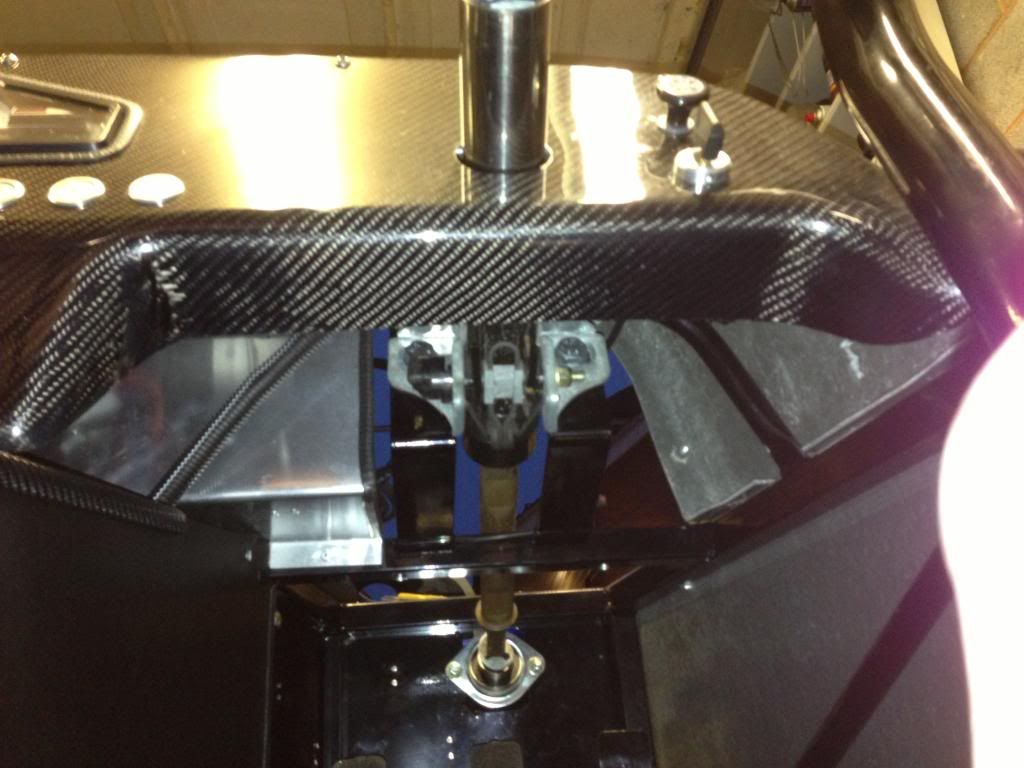

Passenger side

Drivers side before

Drivers side after

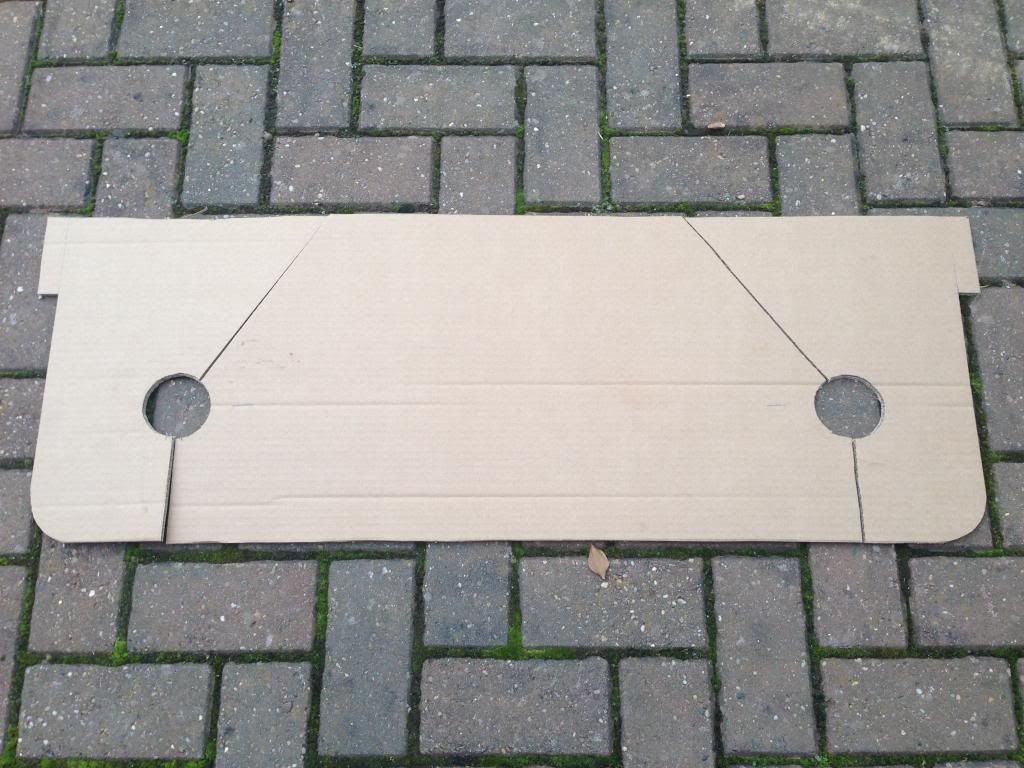

Other job today was to change the number plate light as the one I installed had a really sharp edge on the bottom which didn't meet the edge radius requirements.