Started

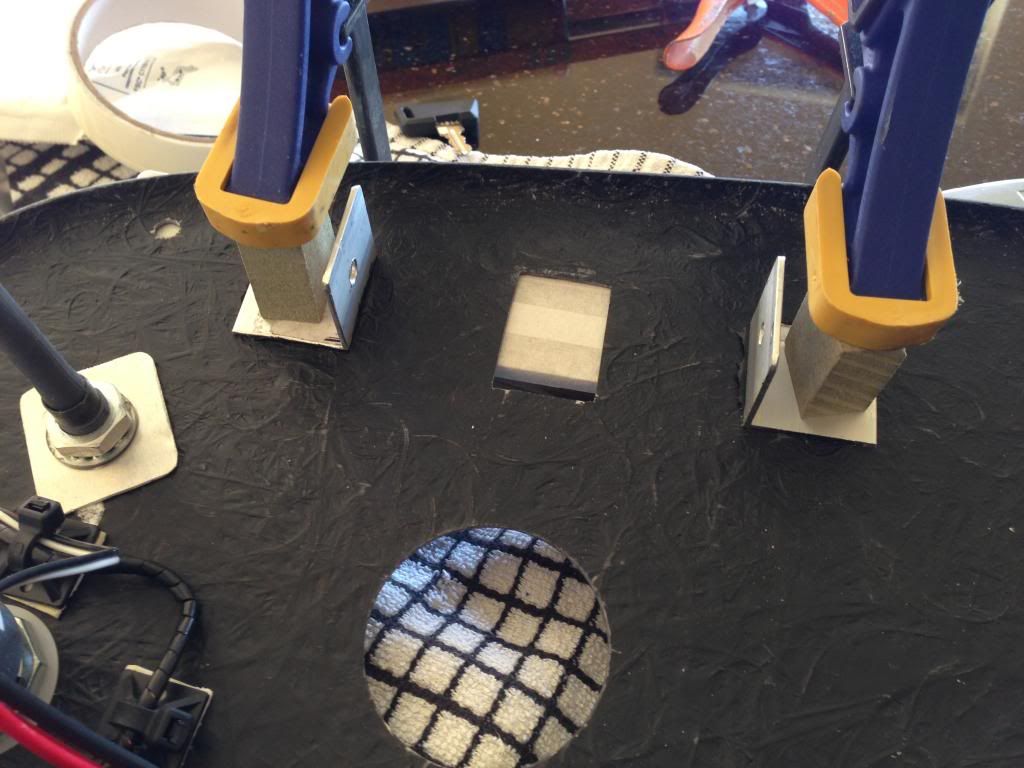

the day by fixing the brackets for the gear indicator to the back of the

dash. I did this in the same way as I

mounted the clocks, by fixing two aluminium angle pieces using sikaflex. Surfaces were keyed to ensure good adhesion.

Next

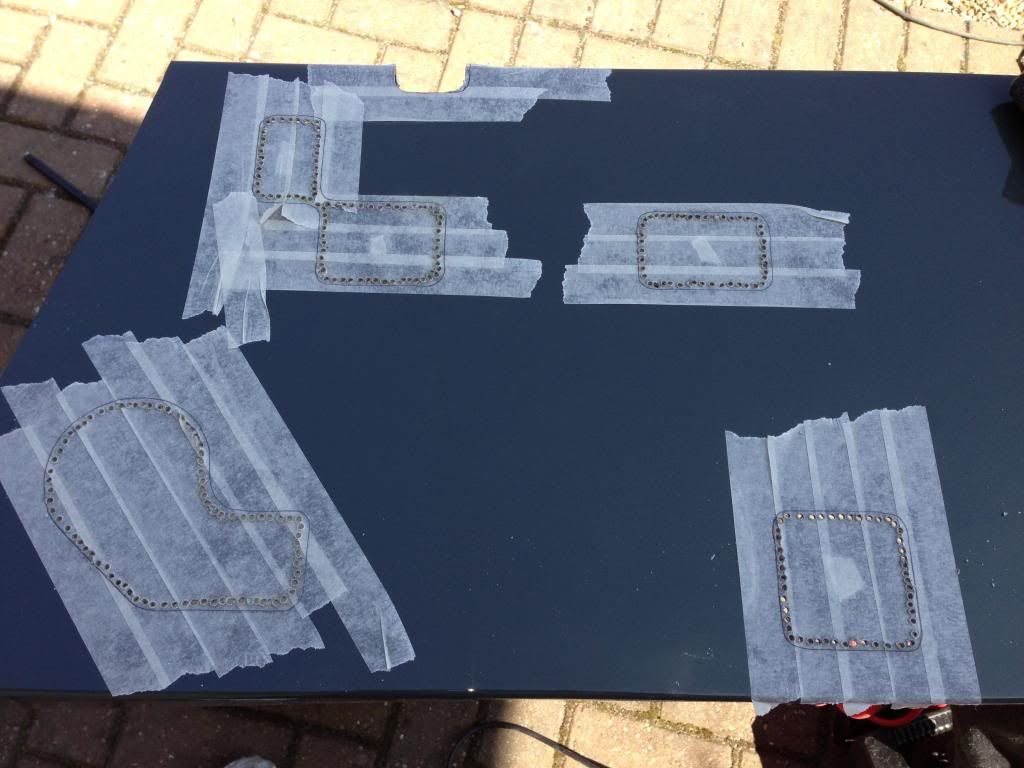

job was the side panels. I measured the

distance from the bend in the side panels to the headlight bracket as this

would be the reference point for my cutting template. The template was then laid on the panel and the

shapes drawn out onto the masking tape.

I used the dremel with a 3mm drill bit and stitch drilled all the

shapes, then used the cutting tool to join up the drill holes and finally the

sanding tool to neaten all the edges.

It turns out I measured slightly wrong so I needed to extend all of the

near side holes by 5mm which was frustrating but you cant really see the

difference.

I

then started on the throttle. First job

was to install a pedal stop behind the pedal to restrict movement. I have used an M8 x 80mm bolt for this fixed

through the bulkhead, held in position by two nyloc nuts. This can be adjusted if needed.

I

then put the bike throttle cable back on the throttle body and measured the

extension required to go from throttle closed to full throttle. This was approximately 20mm. next I

identified the position on the throttle pedal that moved about 20mm when the

pedal was pressed. The pedal was then

drilled to allow the clevis to be fixed.

I

made a pedal stop for the front from a strip of aluminium which was bent to

shape, drilled and fixed by the bolt that holds the pedal in position. I put some edge trim at the top to tidy it

up.

Double checking the template!!

Marked out on masking tape

Stitch drilled

Cut out with dremel

Sanded smooth with dremel sanding attachment

Rear pedal stop installed

Pivot point marked and drilled on throttle pedal

Front pedal stop - bent aluminium and edge trim

When the bike was operational, the throttle operated by twisting the right handlebar had a throttle cable but also a decelerator cable. This pulled the throttle closed as opposed to relying on the spring to close it. I connected up the decelerator cable and attached it to a couple of springs. This test shows that tension on the decelerator gave a better throttle feel with more resistance but also closed quicker when the pedal was released. I will have to find a neater way to install a system similar to this test.

No comments:

Post a Comment