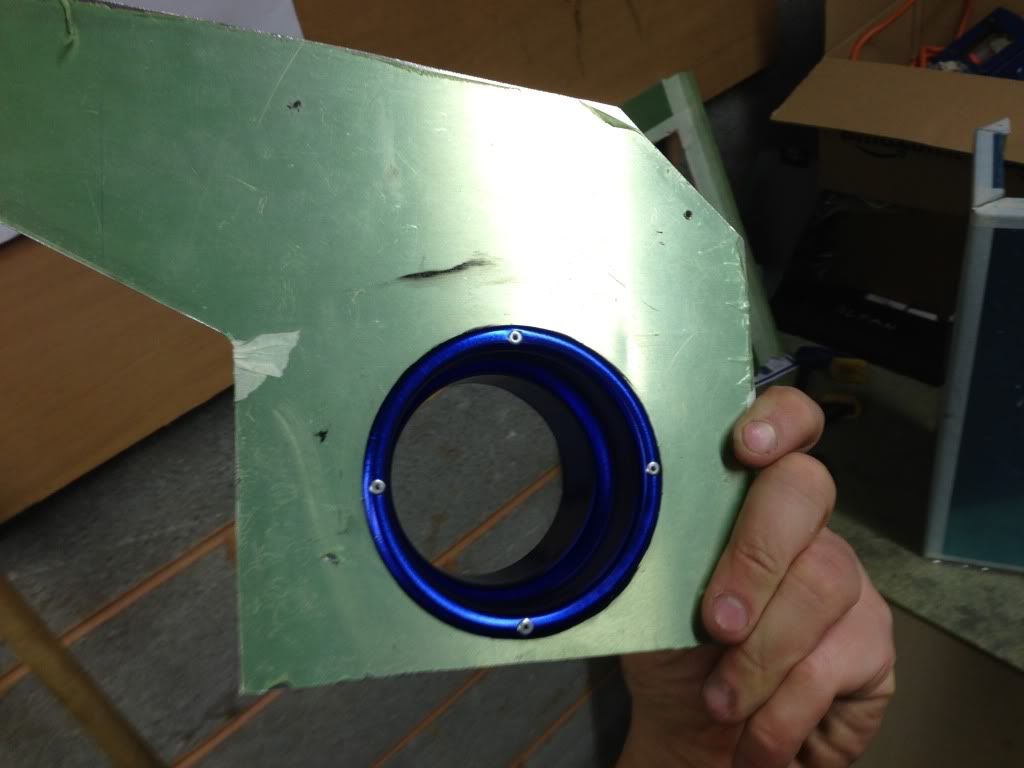

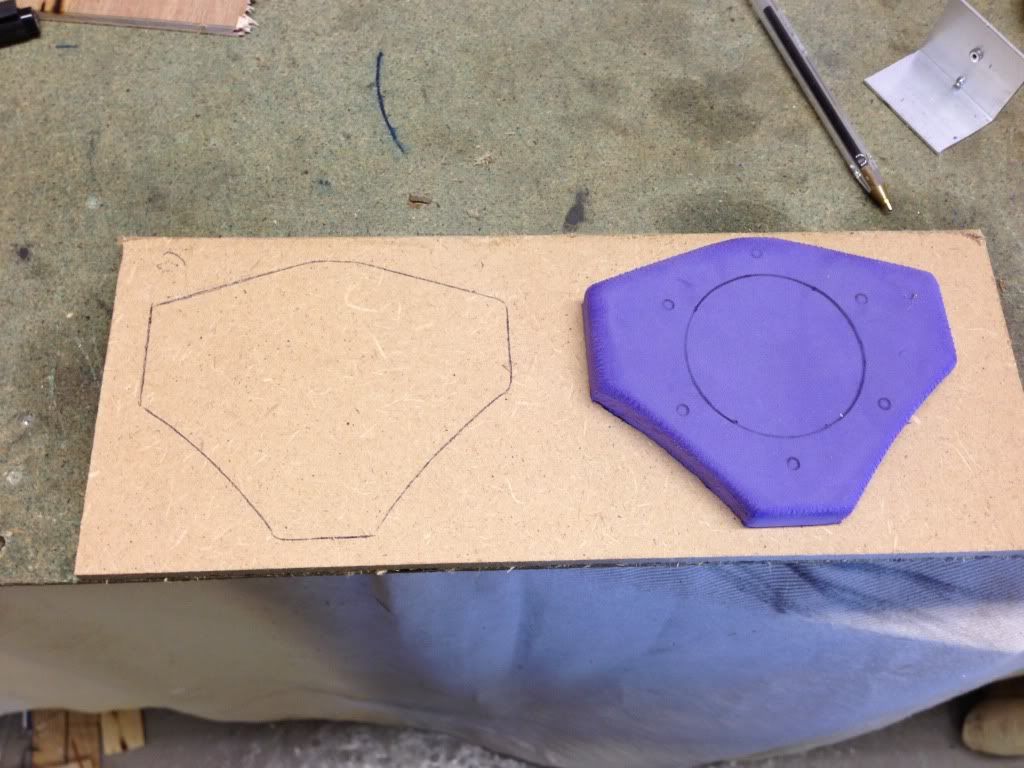

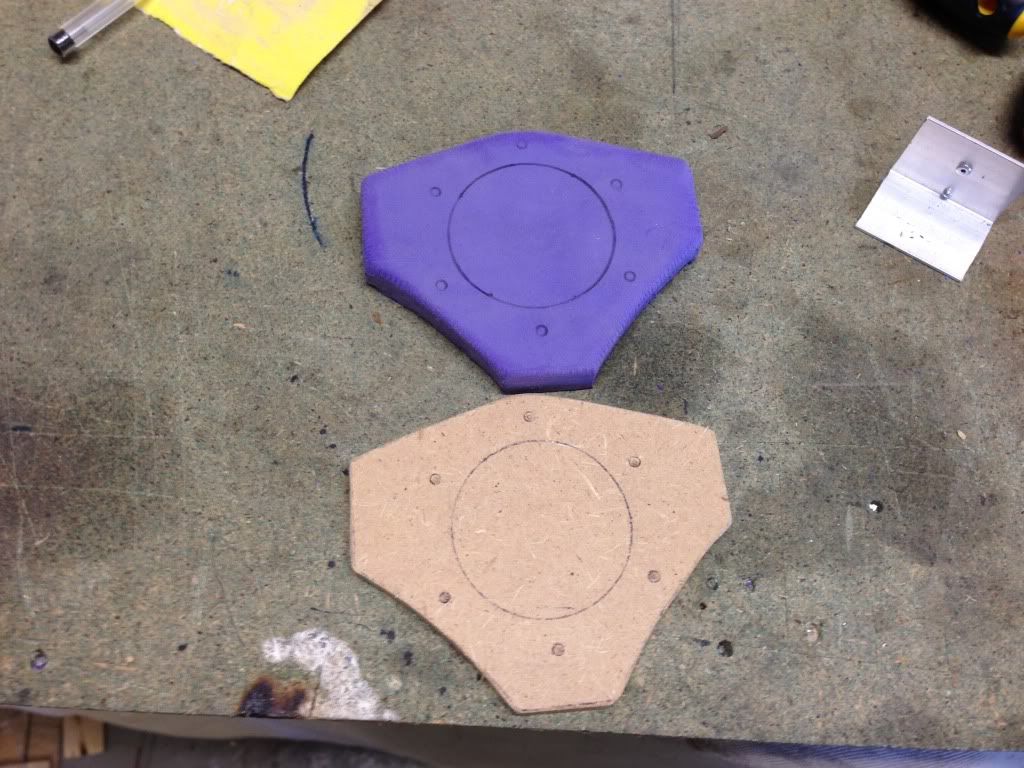

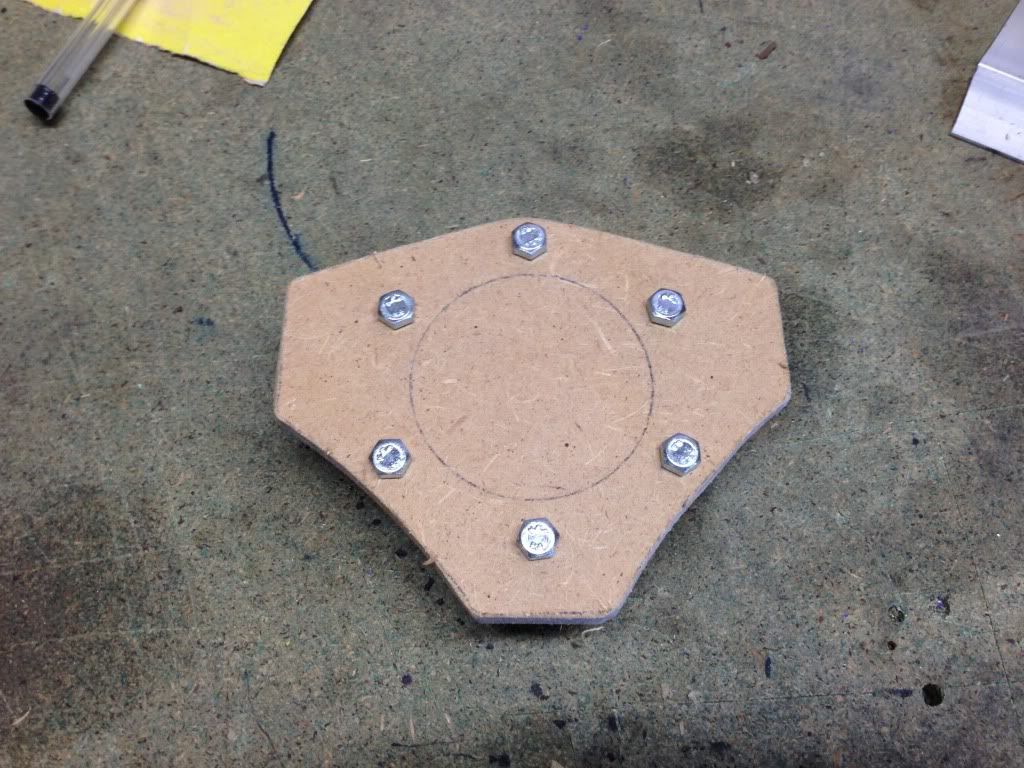

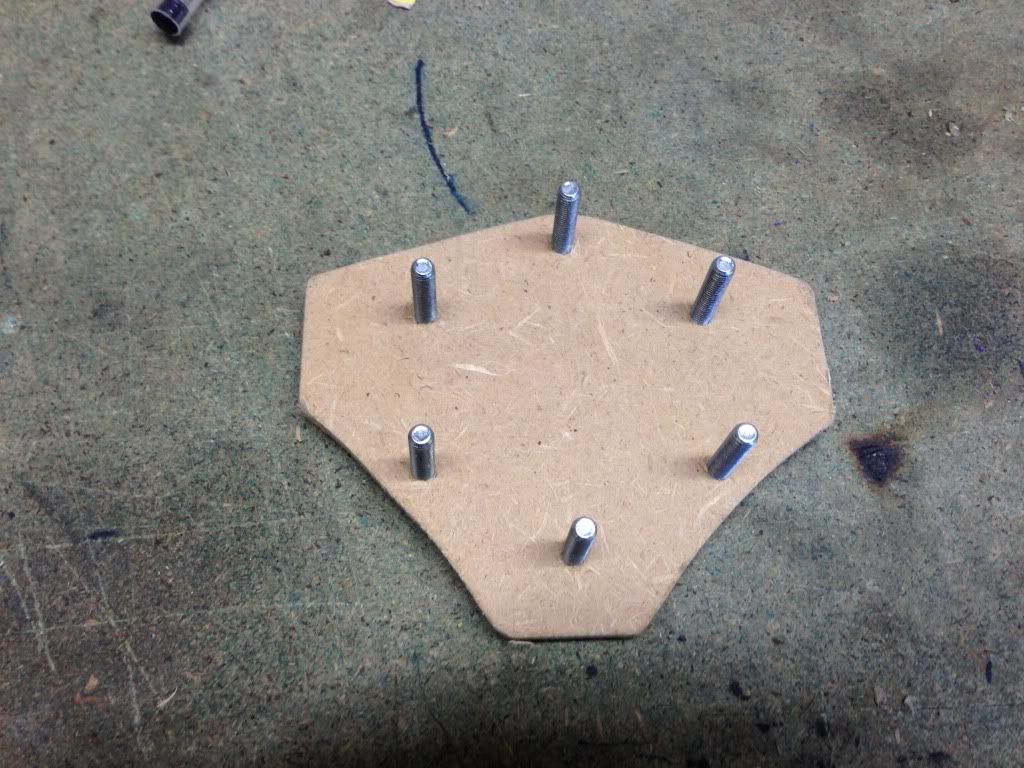

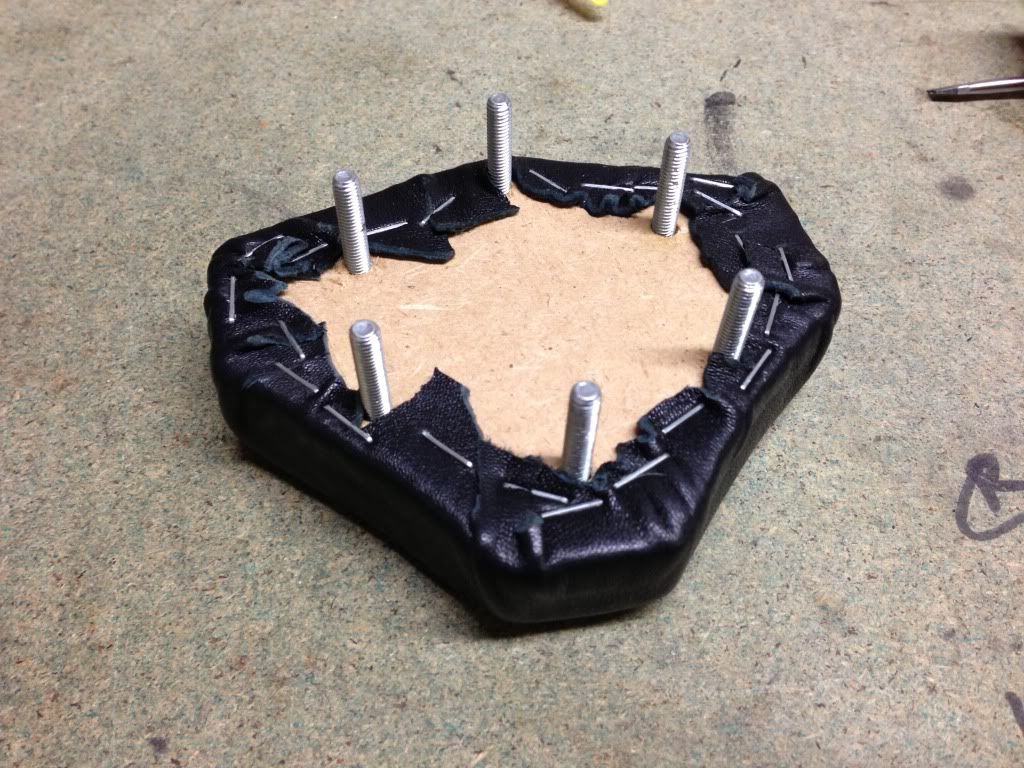

Tonight I fabricated the bracket that will

hold the filter in position. This piece

will be fixed to the internal piece using rivnuts which will allow the filter

to be removed for cleaning purposes.

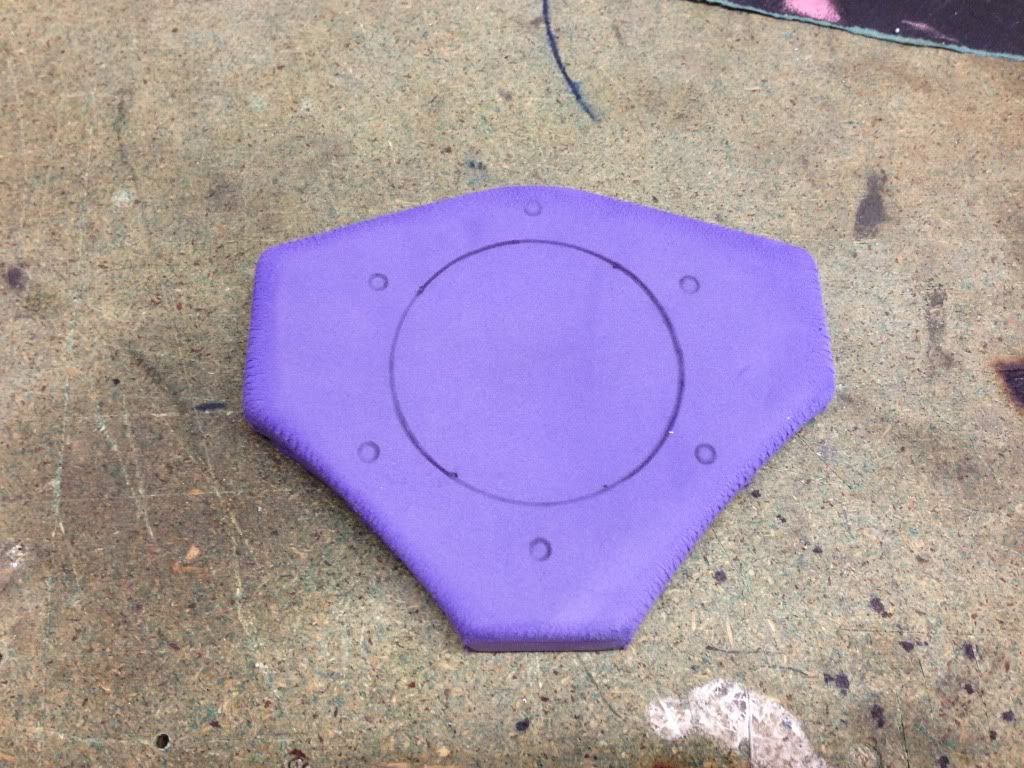

I cut out the filter shape so as not to

cover any of the filter element but to ensure it will hold the filter firmly in

position. The corners were bent and

drilled and rivnuts fixed to the internal piece. The other end will be held in by a small lip

on the internal piece.

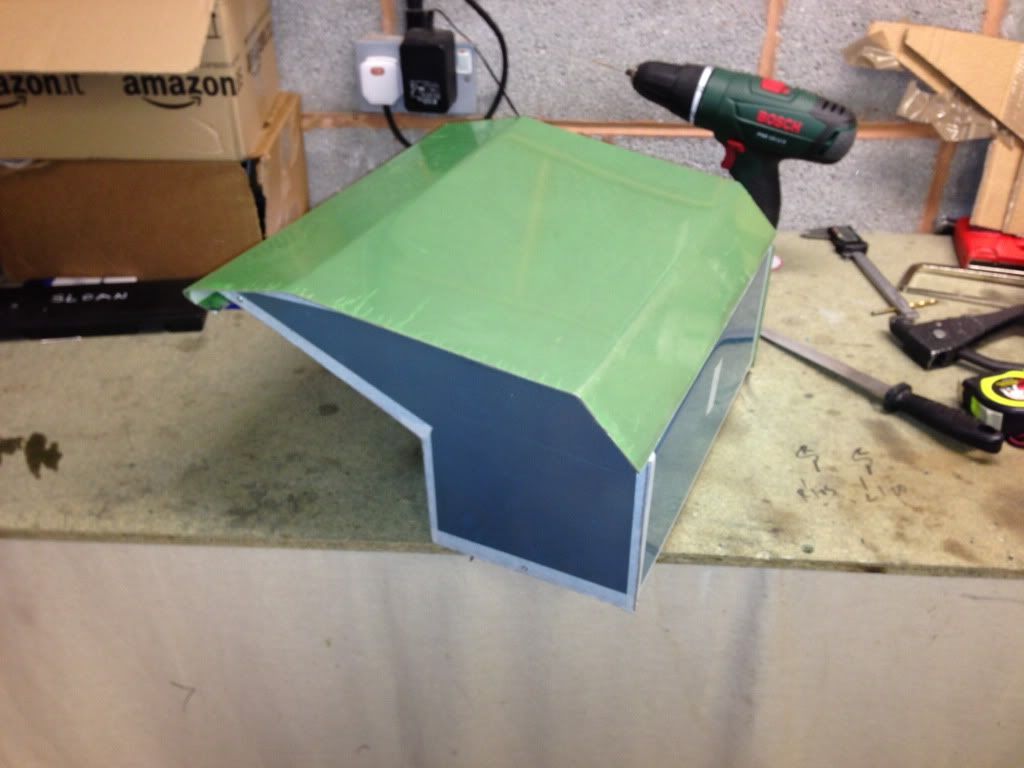

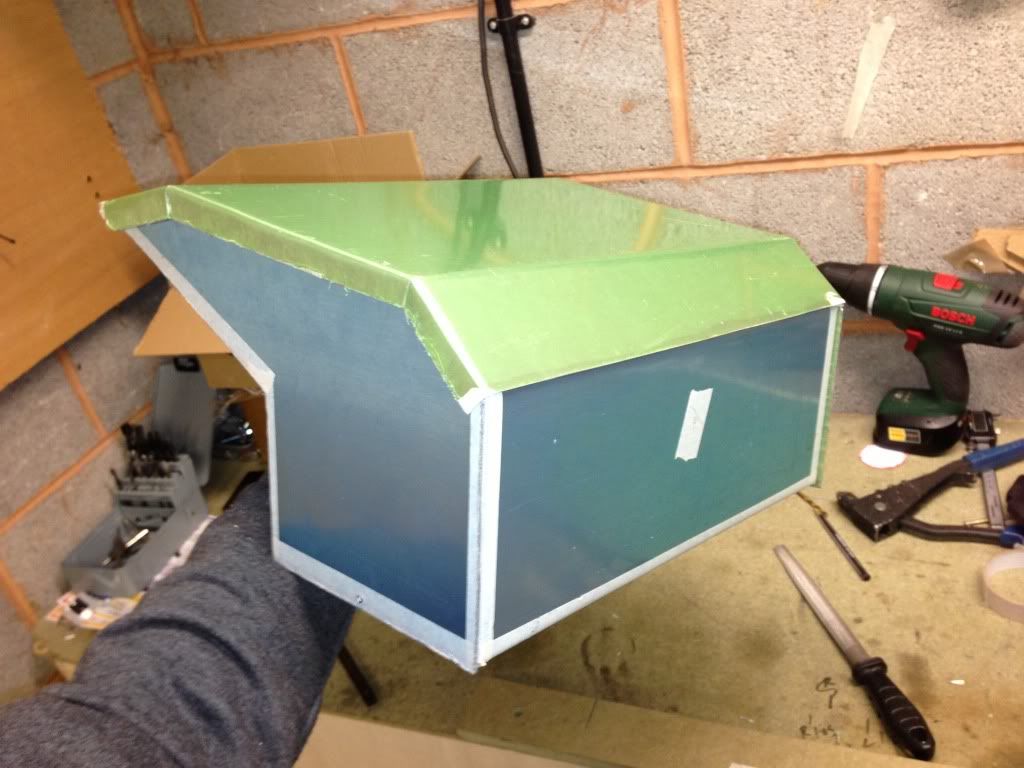

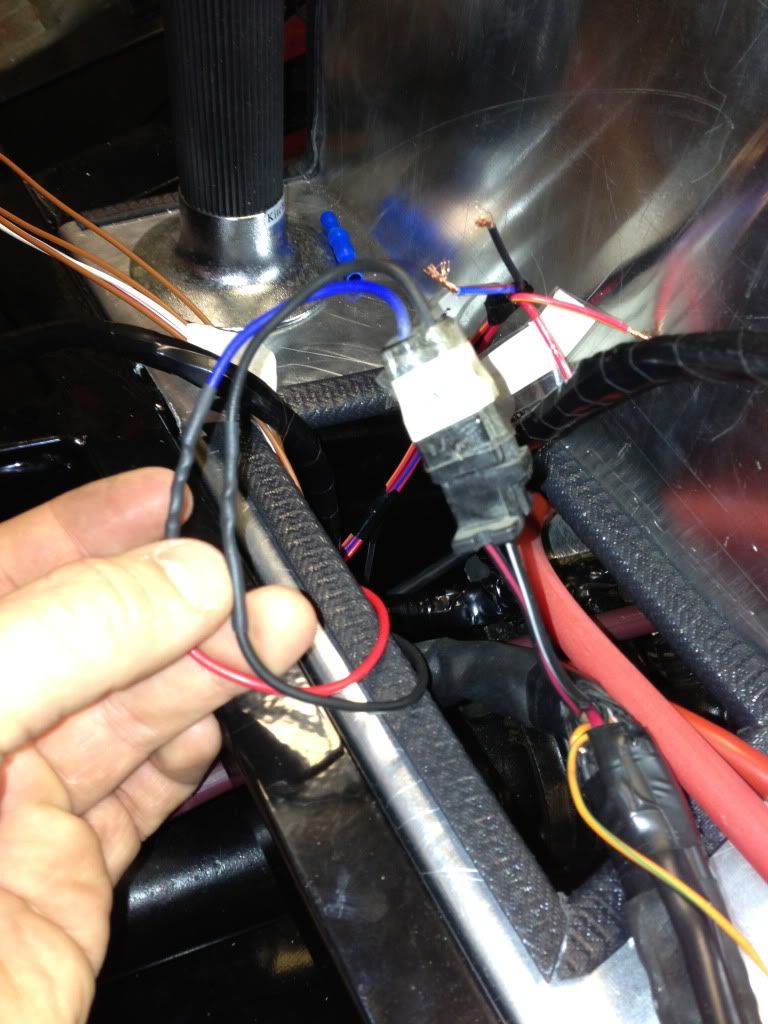

I fitted the internal piece again with sikaflex

and rivets, ensuring that all gaps in the box were fully sealed. It doesn’t look too pretty buy hopefully it

should be airtight and not affect the smooth airflow through the box too much.