Today I hired a trailer and took the car up to MK. First job was to sort the exhaust as there was only 60mm ground clearance to the silencer and it was blowing where it joins the engine. Danny chopped the manifold in half and rewelded it at a different angle. Now the bottom of the silencer is above bottom of chassis so there should be at least 105mm ground clearance. The blowing was caused because I hadnt tightened the bolts fully so Danny replaced them with new ones which solved the issue.

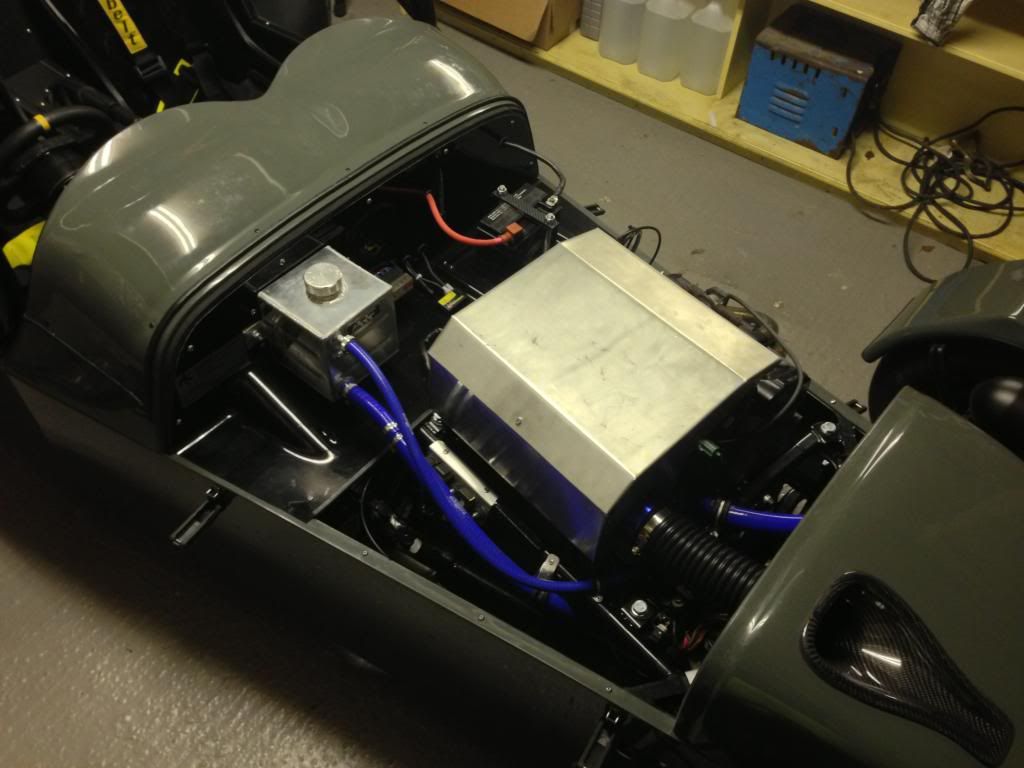

Next job was the emissions. Steve fitted my power commander and hooked it up to his laptop. It only took about 3 attempts to get the lambda and the CO readings within the limits at idle and 3k rpm.

Next job was to sort the speedo healer. I had installed the speed sensor some months ago but it wasnt working. Turns out it wasnt close enough to the prop adapter bolts. Steve adjusted it slightly and it started working. Once working it was programmed and tested until it was reading accurately.

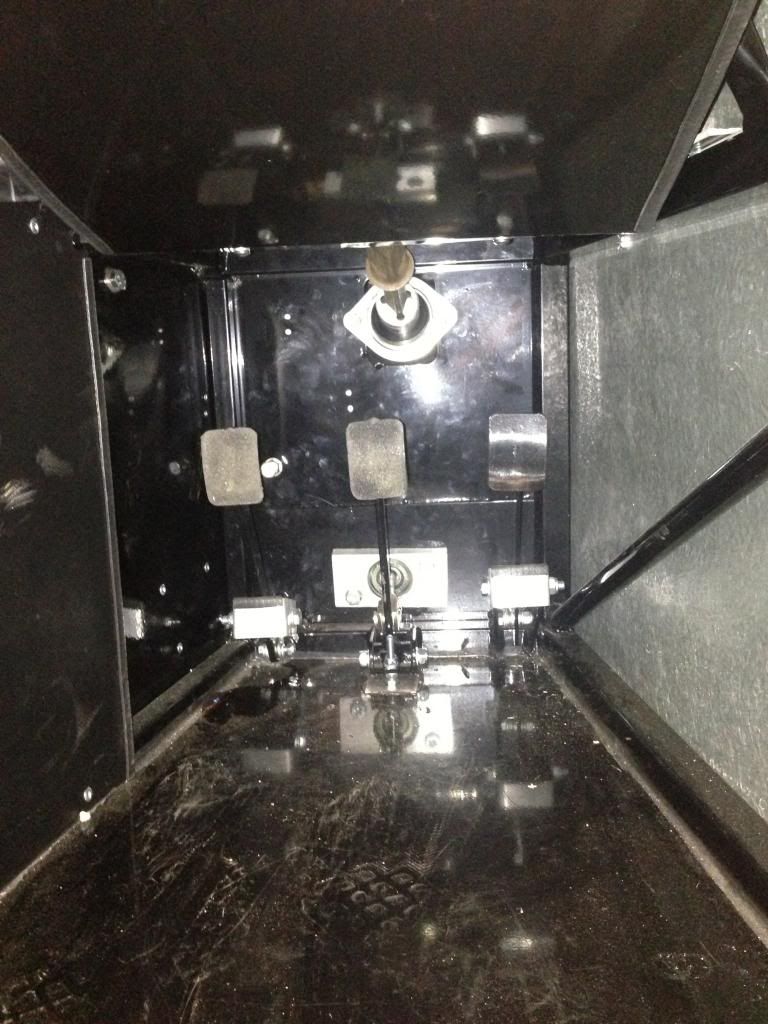

Geometry next. Danny checked rear camber which was bang on. Front needed some adjustment. Undoing the mushrooms was a slight issue as I had installed my cycle wings incorrectly. I had wedged the bracket in the gap where the pinch bolts tighten instead of having it to the side. Turns out I have got the left and right brackets mixed up. Once the cycle wings were removed the upper ball joints were adjusted until there was 1.5 degrees of camber.

Final jobs were tracking and a quick IVA check which a couple of things were spotted, nothing major though!

All in all, a very successful day at MK.

On the way home I wrote up a list of jobs that still need to be completed - approximately 20 small items to resolve. I need to get these done in the next 2 weeks as my IVA is now confirmed for 4th of September!