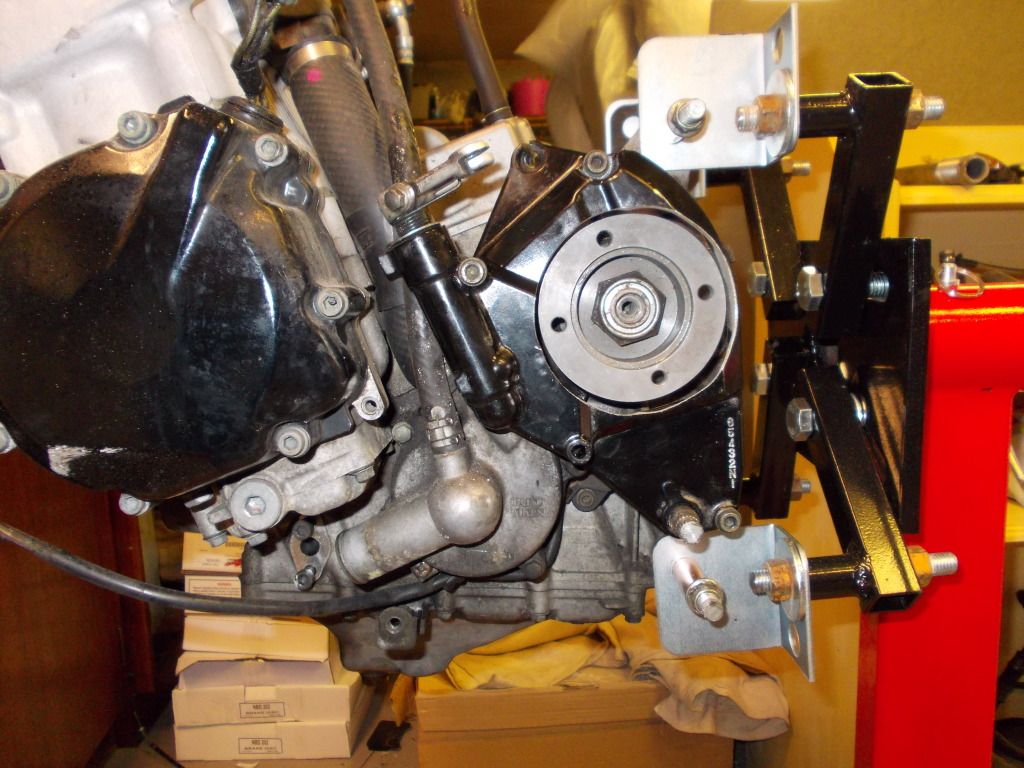

My first attempt at the packer for the

master cylinder at the weekend would have worked but it looked awful, so I

decided to make it again (no pics of the original bit it was horrendous - many pieces of 3mm steel plate welded together)

I cut a 100mm length of 50x25mm aluminium

and marked it up at the right angle (approx. 12o) and cut it using a

small angle grinder with a 1mm blade and a hacksaw. Once cut I smoothed out the cut edge and

marked the centre.

I drilled a pilot hole through and

proceeded to cut out with a 40mm hole saw.

Once through the hole needed increasing to approx. 42mm using a half

round file.

Tomorrow I will drill the two holes for the

fixing bolts and hopefully get the master cylinder fitted.