Today

I had another full day in the garage doing various small jobs. First job was to sort out where the fuses

will be mounted. I decided to mount them

to the fiberglass bulkhead so they can be accessed from under the bonnet which

I prefer the look of compared to mounting them under the dash. I marked the hole and drilled 2no 7mm holes

for the M5 rivnuts. The hole was then

cut out using the dremel. I then cut a

small length of edge trim to cover the edges (will need to be removed to get

the fuse box through).

Next

job was to fill the diff with oil. The

drain plug in the back of the diff should take a 10mm allen key but it appeared

to be rounded so I couldn’t get it off. To begin with. Fortunately I managed to undo it with a set

of pipe grips. I filled the diff with

EP80w-90 gear oil using the tube that came with the bottle. I had read online that it should take about

900ml but I put the whole bottle in and then checked the level using a bent

piece of wire. The level is about 10mm

below the bottom of the drain hole which is exactly where it should be.

I

then welded on the socket cap of an M12 bolt to the drain plug so it would be

easier to remove in the future.

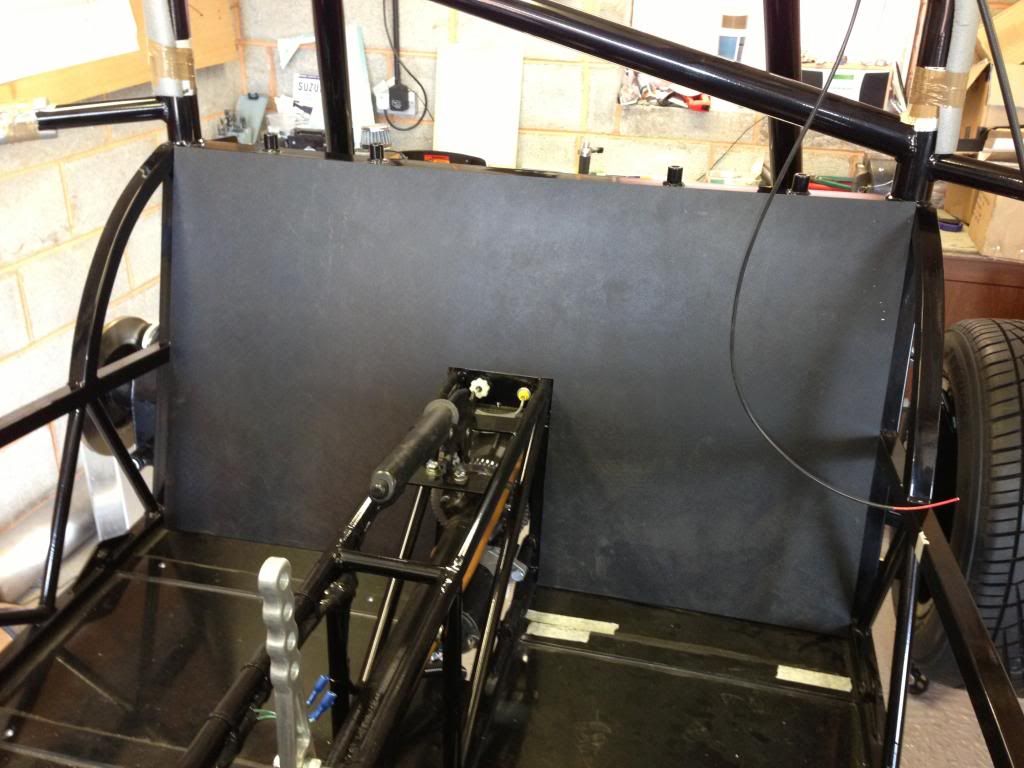

Final

job for the day was to start on the interior panels. The panels come almost cut to size from MK, a

small bit of trimming is required. I cut

about 4mm off one side of the rear panel to get it to fit and then covered the

top in edge trim as the edge was sharp and would be exposed. The tunnel side panels were next and again

some trimming was required along the back edge.

I then notched out for the seat rails and a couple of chassis rails. I used the dremel with a diamond cutting disk which seemed to do a good job.

I still need to cut out for the harness

bolts.

Hole marked for fuses

Fuse box mounting on fibreglass bulkhead

4no x M10 x 30 - fine pitch

Prop to diff bolts in

Drain plug rounded off

M12 socket cap bolt head to be welded

Welded to drain plug

Interior back panel cut to size

tunnel side panel marked for cutting

No comments:

Post a Comment