Today I finished off the cycle wing brackets. I wasn't happy with yesterdays efforts so I cut off the top of all the brackets. I the bought a length of 20mm x 4mm steel bar from B&Q and cut it into 500mm lengths. I carefully marked and bent each one in the vice - comparing the new brackets to the others it can be seen how much neater the bends are.

Next I cut 50mm off of each of the tube parts of the brackets which would allow me to crush in a vice and install the new flat bar ready for welding. I needed to grind the flat bar to a point so it fitted but once it was in the tube it was a tight fit. I tested this before I cut it to make sure it would work.

I then welded the new top half of the brackets in position and cleaned up with the abrasive wheel ready for powder coating.

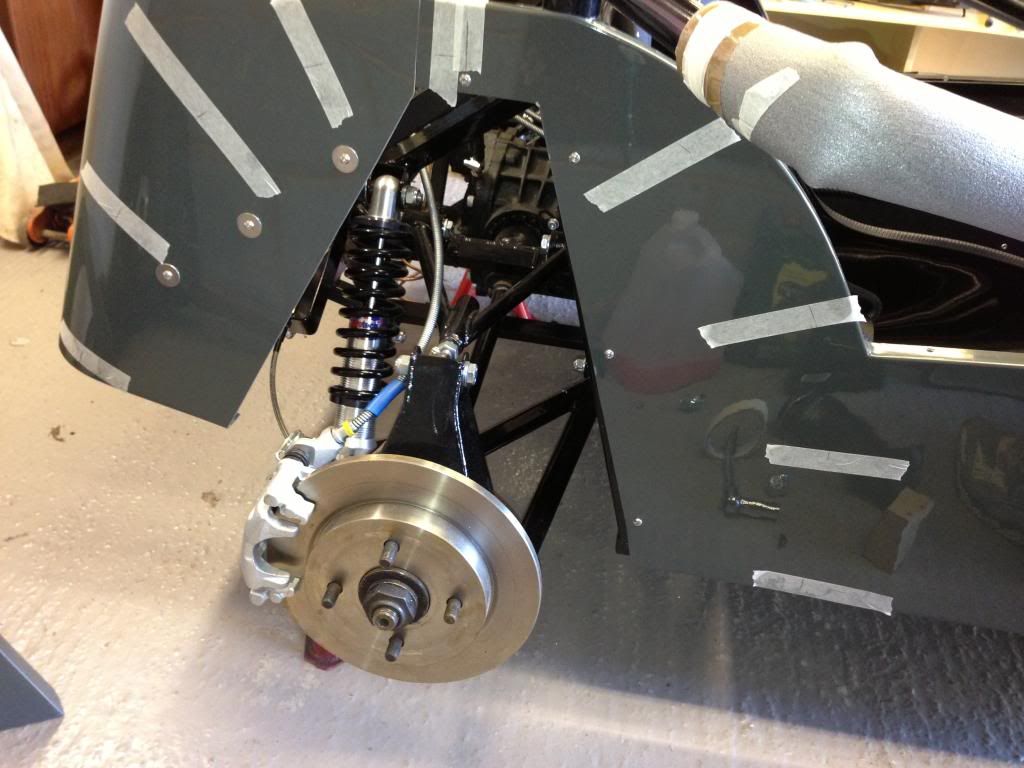

Next job was the rear arches. I looked at a few pictures online and it appears that the front and rear of the rear arch are in line with the bottom of the side panel. This meant I just needed to line these up and centralise the wheel to find the position. The arch was then clamped in position and drilled through with a 2.5mm drill bit in 6 positions for the rivnuts. These holes were extended to 7mm and stainless rivnuts installed in the side panel. I am not quite sure how but the offside arch ended up 20mm too far back which meant I had to redrill for new rivnuts. Fortunately the other 6 holes will be hidden so it wont be too much of a problem.

Finally I installed the rubber trim between the arch and side panels.

New bends compared to first attempt

50mm cut off tube of brackets

Testing position of cycle wing

Testing the flat bar in the tube

Welded in position and cleaned with abrasive wheel

New bracket in position - about 25mm clearance to wheel

Marking position of rear arch

Near side arch complete with rubber trim

Offside arch was installed 20mm too far back. I had to redo the rivets. Holes cant be seen though

Completed offside arch

No comments:

Post a Comment