My

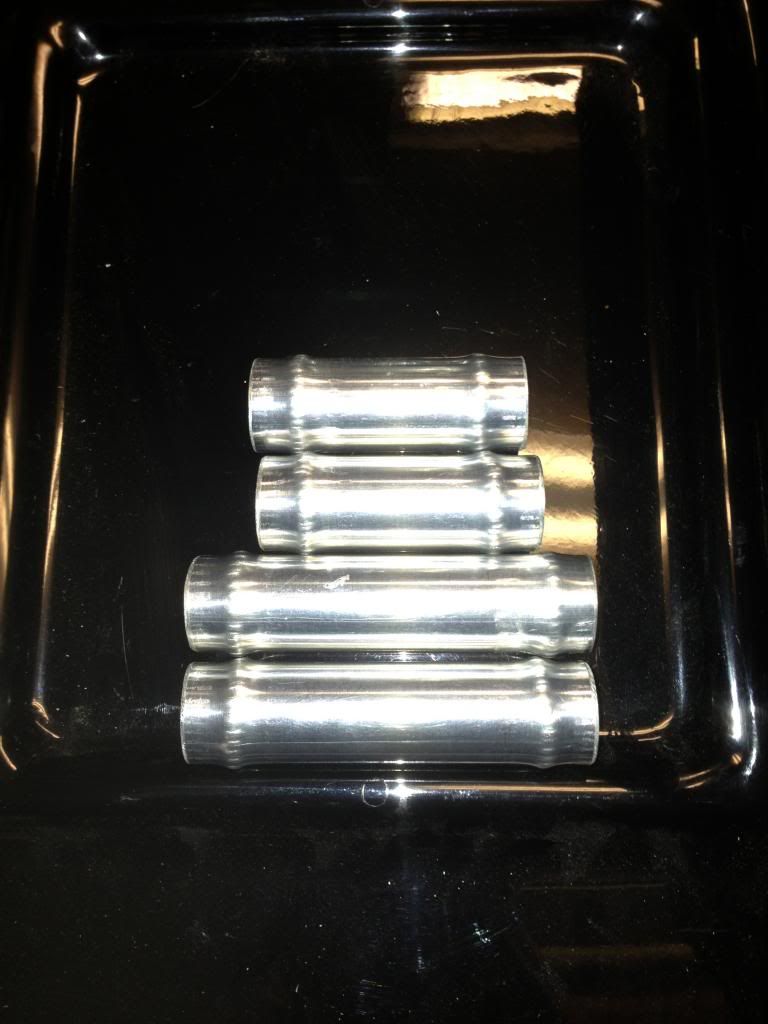

25mm alloy pipe arrived today so I made a start on making connector pieces with

beaded ends. This worked well with my

homemade beading tool.

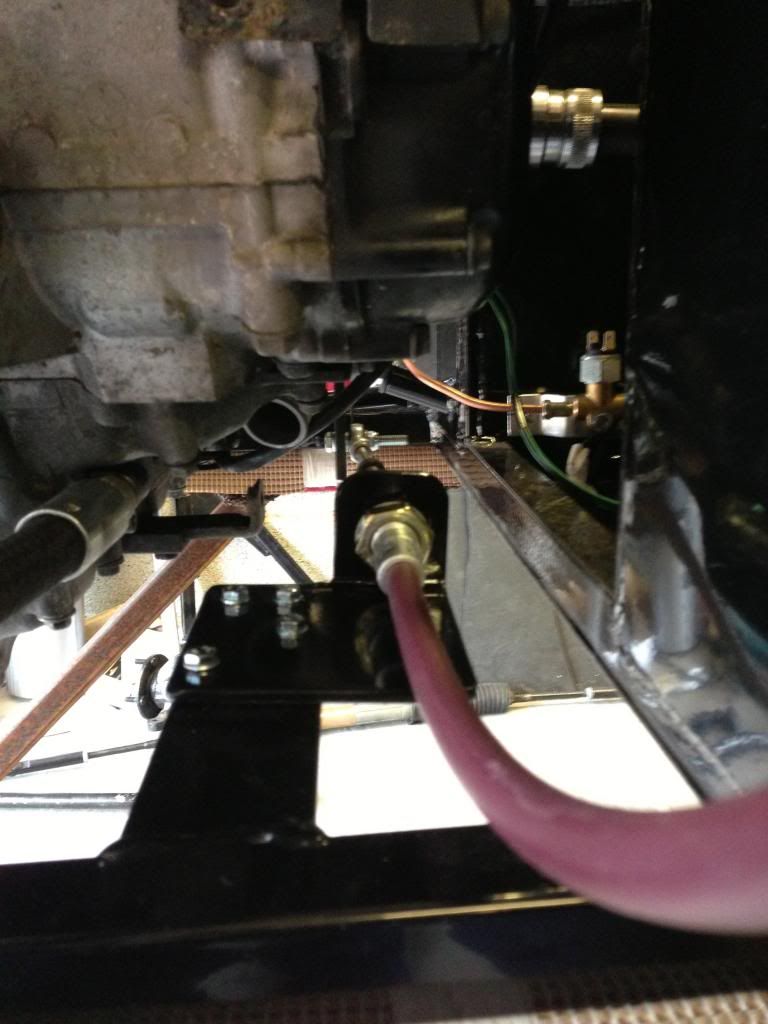

I

then bolted the new gearshift bracket in position so I could see how much room

there would be for the hose to the water pump.

Next I laid out the silicone hoses to get the correct lengths before

cutting.

The

hose from the thermostat to the top of radiator needed to bend quite a bit and

when I tried with a straight length of hose, the hose would occasionally

kink. This wasn’t ideal so I remade a

couple of the connector pieces but I made them curved (I did this by using a

25mm pipe bender). Adding these two

bends made the route a lot easier to make with silicone hoses. I used a homemade P clip to secure the hose

to the engine cradle.

I

made another curved connector piece for the hose from the water pump, which

will ensure that the hoses from the pump are not touching anything, so aren’t

at risk from wearing through.

Last

job was to start on the decelerator cable which will help close the throttle

bodies and give better throttle feel. I

had seen an idea on Locostbuilders where a spring on the end of the cable could

be used so I had a go at that. I bought

a set of compression springs from Screwfix and chose the one that would give

enough tension – the spring was a bit long so I had to chop it down. Next I made a couple of spring guides from

1.2mm aluminium. The photos show how

these are used, along with a cable clamp, to attach the spring to the end of

the cable. I need to make some

adjustment to the throttle cable as the decelerator cable now stops the

throttle opening all the way.

Connector pieces with beaded ends

New gearshift bracket fitted. Cable in position

Hoses laid out in position

Curved connector with beaded ends

Top hose complete

Top hose in position

Top of radiator. 8mm outlet capped off

Spring guides. Used a holesaw without drill bit to cut halfway through aluminium

Guides cut out

Fitted to decelerator cable

No comments:

Post a Comment