I spent the day making the airbox I modeled

out of cardboard from aluminium. I chose

1.2mm sheet as this was strong enough but also easy to bend into shape.

The box was bend to shape using MDF as a

guide and G clamps to hold. The

aluminium was then bent by hand.

I marked out the 4no holes for the trumpets

(55mm holes at 80mm centres) and filed the edges smooth. I installed the trumpets and put the box on

the engine to check the bonnet clearance.

The first few attempts didn’t fit and I ended up cutting off the 20mm

lip I left for attaching the lid. I also

had to bend the box more than planned so as to ensure the bonnet didn’t catch.

I decided against sealing the airbox against the bonnet so decided to make a lid for it, again using 1.2mm aluminium sheet. This is a tight fitting lid that

will be held in place with screws and clips.

I will use some adhesive foam to form an airtight seal. With the bonnet in position the airbox just

catches but I couldn’t reduce the height any more or it would restrict airflow

in the trumpets. I can fix some foam to

the top of the box to cushion it against the bonnet at a later date.

I have designed this airbox to use the

original bike air filter. I will also

install an intake hose from the side and position it somewhere where it will

get cold air from (possible infront of the radiator or a vent in the side of

the nose cone.

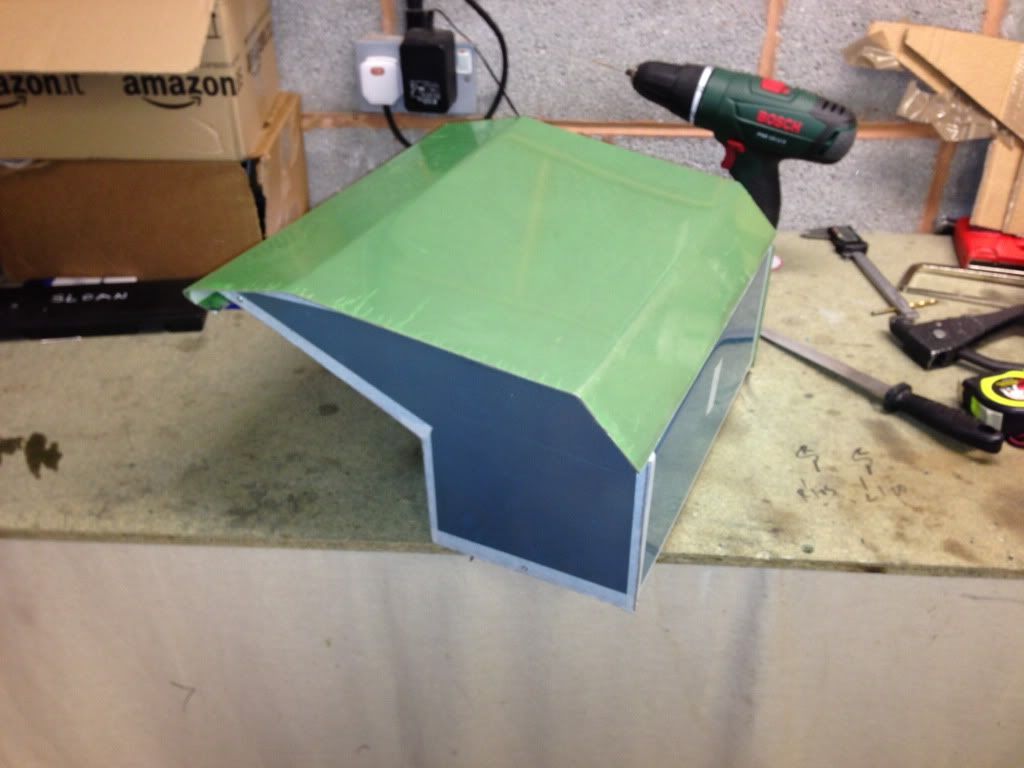

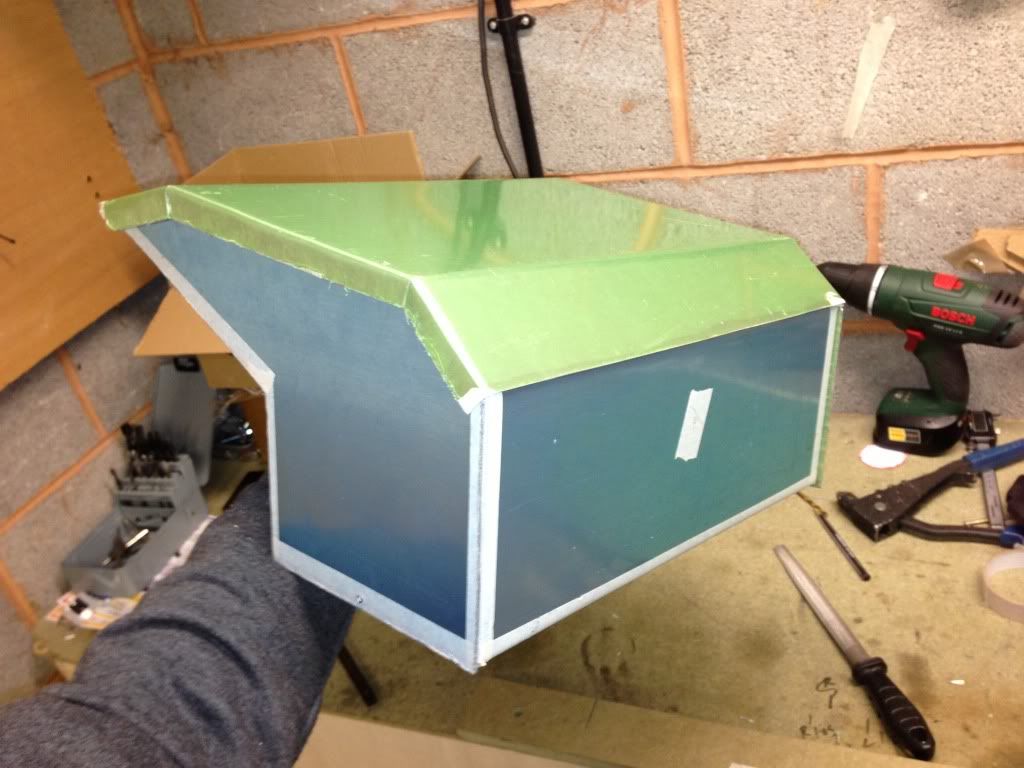

Bend to shape

Sides cut to shape

Lid bent to shape

No comments:

Post a Comment